Since much of the world is using luminaires designed to ANSI C136 Standards, backward compatibility is important when updating light fixtures. However, Zhaga/D4i dual-node architecture is destined to become the backbone of smart city infrastructure. Our LUMAWISE Endurance products may be the key to implementing a hybrid solution.

STREET LIGHTING ARCHITECTURES

ANSI C136.10

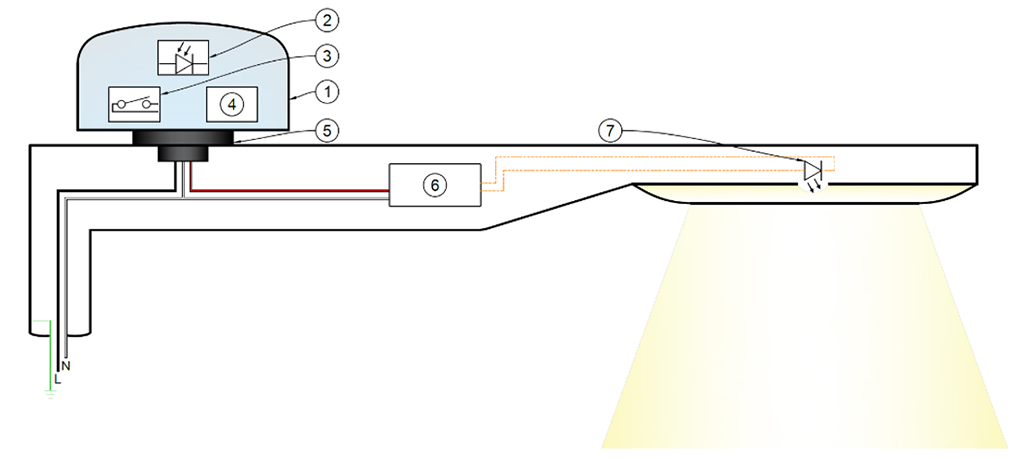

Non-Dimmable, 3-Pole Photocontrols

Around a decade ago, most streetlights were incandescent with photocells to turn them off during daylight hours. The ANSI C136.10 Standard for Roadway and Area Lighting Equipment provided a common platform for interchangeability of photocontrols and receptacles based on ac line voltage with 3-pole connections. In North America, the roadway and area lighting market developed ANSI C136.10 as the standard interface, while it became the de facto standard in much of the world.

(1) Control Device – ANSI C136.10 Certified; (2) Photodiode; (3) Switched Voltage to LED Driver; (4) Power Supply Unit (PSU); (5) ANSI C136.10 Interface; (6) LED Driver; (7) Light-Emitting Diode (LED) Module.

ANSI C136.41

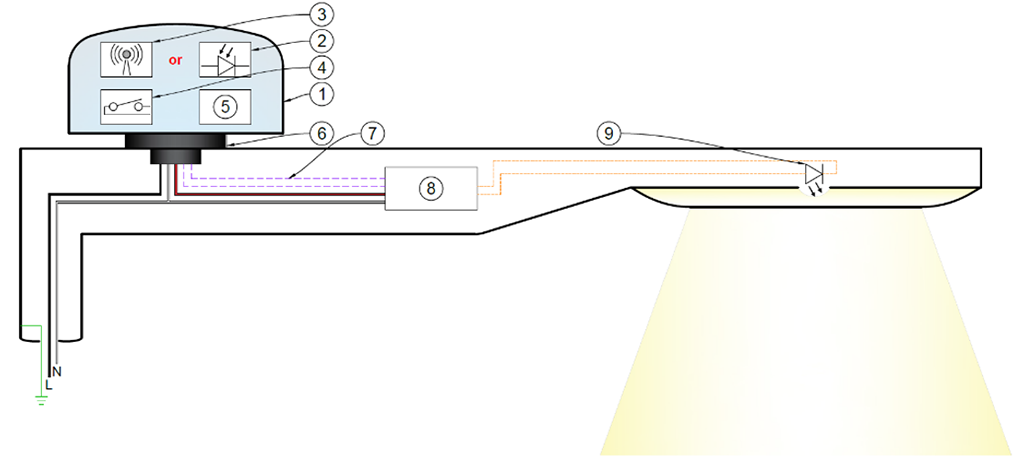

Dimmable Photocontrols

As energy costs have risen and LED technology has become more prevalent, ANSI C136.41 was developed to define devices and receptacles for increasing the efficiency of roadway luminaires. Created to be backward compatible with existing lighting systems, this standard maintains the 3-pole line voltage connection and adds contacts for signal output. This interface allows for either digital or analog dimming control by a photodiode or motion sensor.

The architecture is designed to have grid power routed into ANSI C136.41 photocontrol and will switch that power to the LED driver. An internal power supply unit (PSU) converts that grid power to a logical voltage to power the controls. Often in North America, the dimming signal is analog (0-10V) which is perceived to be inexpensive and reliable. Networking of the streetlights is achieved through a variety of wireless protocols.

The ANSI C136.41 Standard does not provide many details about how to include sensor inputs into luminaires. The wide variety of wiring configuration choices make it challenging to optimize components. Also, the 0-10V analog control output limits the lighting fixture to only one input. However, there is considerable effort to include the D4i protocol, based on DALI-2, in future standard updates to address this.

(1) Control Device – ANSI C136.10 Certified; (2) Photodiode; (3) Wireless Communication to the Cloud; (4) Switched Line Voltage to LED Driver; (5) Power Supply Unit (PSU); (6) ANSI C136.10 Interface; (7) Dimming Signal – Analog or Digital; (8) LED Driver; (9) Light-Emitting Diode (LED) Module.

Zhaga Book 18

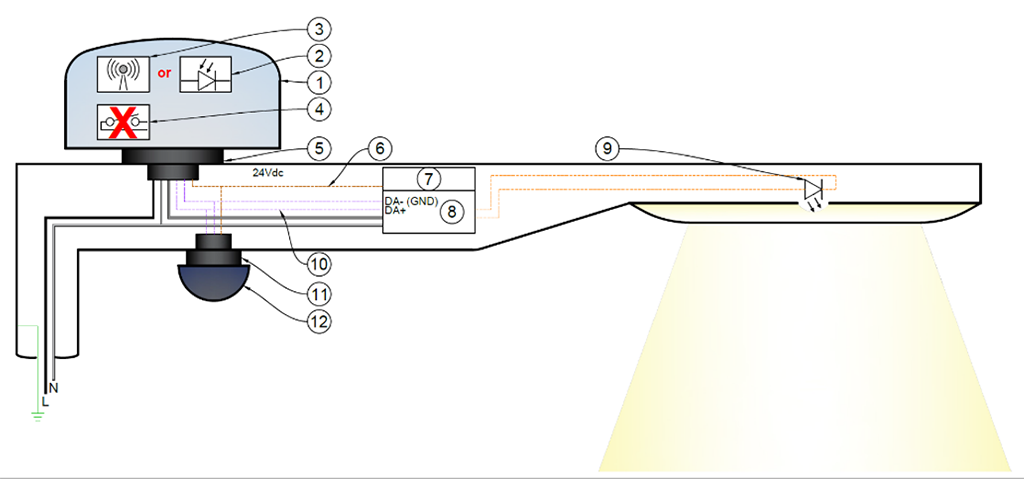

Dual-Node Architecture

In 2010 Zhaga, a global lighting industry consortium, was formed to standardize LED component interfaces in luminaires. Recently, their mission has expanded to include interoperability of components. In partnership with The DALI Alliance, they have developed the D4i protocol and certification program for IoT-ready lighting fixtures. The Zhaga Book 18 Standard was designed specifically for LED lighting and differs from ANSI C136.41 in that the PSU is incorporated into the luminaire instead of the photocontrol, either as part of the LED driver or separately. This simplifies wiring of the lighting fixture’s control nodes and allows for dual-node architecture.

The dual-node architecture incorporates an upward facing node, to house a photocell or communication node, and a second node for motion or other sensor types for which a downward viewing angle is appropriate. The communication bus is designed specifically for D4i protocol. The sensor nodes themselves are smaller and easier to seal against ingress from dust and precipitation. With a new generation of interchangeable drivers, Zhaga expands the capabilities of outdoor lighting fixtures to act as a platform for sensors as well as communication devices. In the future, we expect to see sensors for vehicle or pedestrian counting, traffic reporting, pollution detection and other purposes.

(1) Control Device – Zhaga-D4i Certified; (2) Zhaga Book 18 Interface; (3) Auxiliary Power; (4) Built-In Auxiliary Power Supply Unit (PSU); (5) LED Driver; (6) Light Emitting Diode (LED) Module; (7) D4i Communication Bus; (8) Zhaga Book 18 Interface; (9) Control Device – Zhaga-D4i Certified.

Zhaga/ANSI

Hybrid 2-Node Architecture

Hybrid 2-node architecture leverages the dominance of ANSI C136.41 while taking advantage of the simplicity and open architecture of Zhaga-D4i. In this configuration, the upward-facing node is a photocontrol or communication node connected by a 7-pole ANSI C136.41 interface that does not switch the grid power to the LED driver. The downward-facing node is a sensor input device such as a motion sensor. Both nodes and the entire luminaire are certified to Zhaga-D4i.

The ANSI C136.41 node can be powered from an auxiliary PSU, internal or external to the driver, or the DALI bus. The resulting light fixture design has simplified wiring and architecture and creates infrastructure to facilitate smart cities with Zhaga Book 18 sensors and digital communications protocol.

(1) Control Device – Zhaga-D4i Certified; (2) Photodiode; (3) Wireless Communication to the Cloud; (4) Power Supply from Grid – Not Switched; (5) ANSI C136.41 Interface; (6) Auxiliary Power; (7) Built-In Auxiliary Power Supply Unit (PSU); (8) LED Driver; (9) Light-Emitting Diode (LED) Module; (10) D4i Communication Bus; (11) Zhaga Book 18 Interface; (12) Control Device – Zhaga-D4i Certified.

LUMAWISE ENDURANCE SOLUTIONS

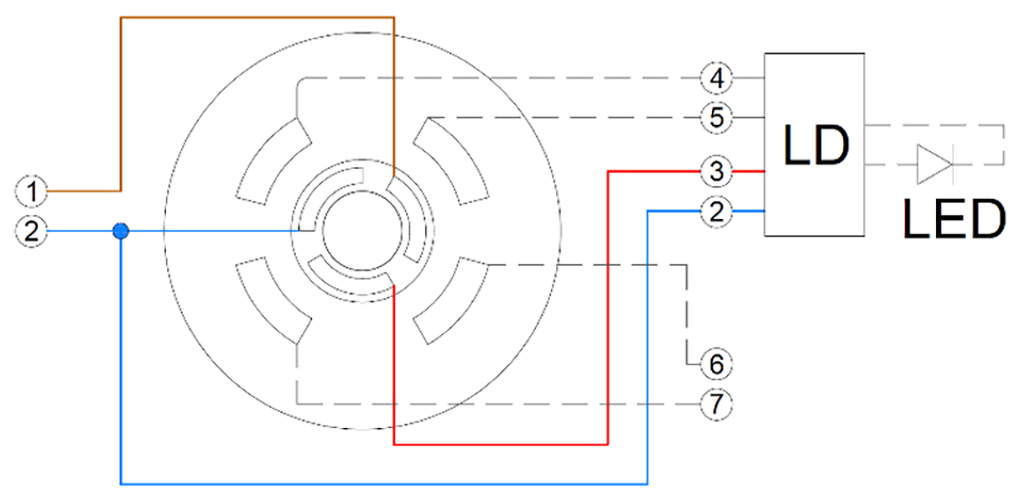

Endurance N Receptacle: (1) Line Voltage from Grid; (2) Neutral; (3) Switched Voltage to LED Driver; (4) DA- (Ground); (5) DA+; (6) Logical Signal Input (LSI); (7) Auxiliary Power Supply Unit (24Vdc); (LED) LED Module; (LD) LED Driver.

LUMAWISE Endurance N Solutions

NEMA/ANSI C136 compliant Endurance N components provide a robust interface that supports 0-10 VDC analog dimming or D4i control systems. Whether designing an ANSI C136 Single Node Luminaire or a Hybrid 2-Node system, TE has a product solution. Dimmable receptacles for 5/7 pole connections can be fixed or rotatable for perfect alignment of the photocell. In addition, they have developed a rotatable receptacle that does not require tools.

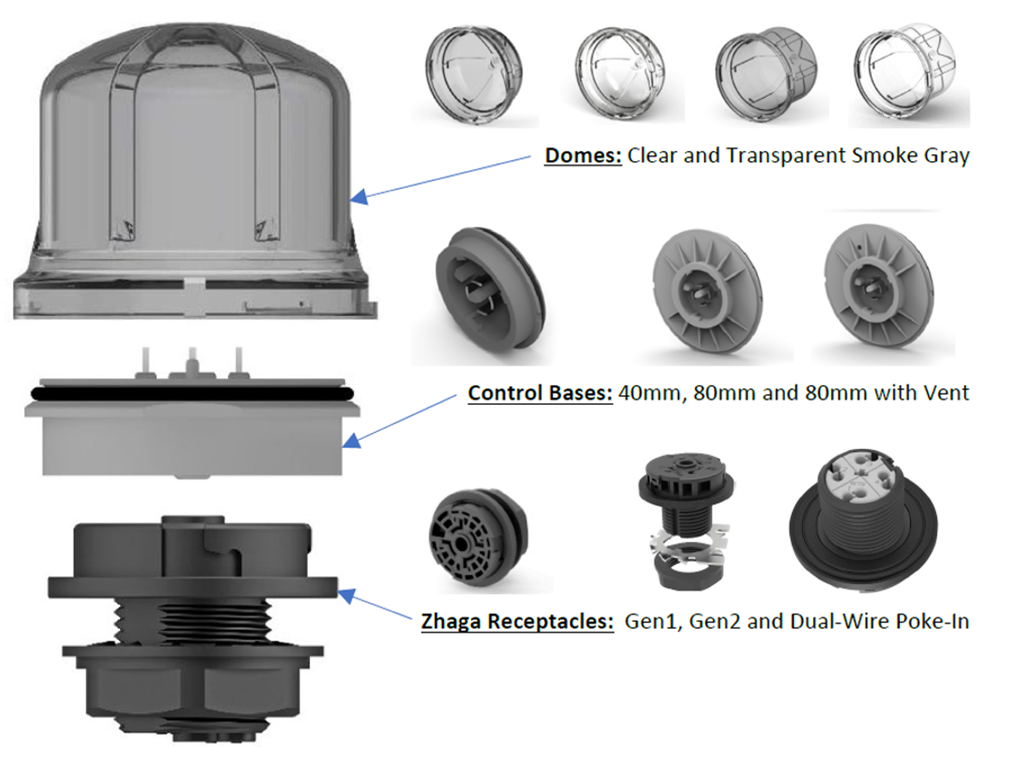

A standard Endurance N base includes the C136 interface with additional contacts for controlling the LED driver and/or an auxiliary PSU. The enhanced base includes a built-in PSU. The cost effective pre-certified design features a layout that has undergone thermal analysis and vibration testing. Control device covers are available in clear or transparent smoke gray and in a variety of sizes.

LUMAWISE Endurance S/S2 Components

Developed as solutions to the smart city ecosystem, the Endurance S and S2 products are sensor-ready solutions for the future of road and area lighting. The Zhaga Book 18 connectors from TE Connectivity enable DALI controlled Zhaga-D4i compliant luminaires.

As a key element to the future of smart cities these components are designed to adapt to new sensor technology as it develops. In the meantime, the IP66 rated receptacle, base and dome combinations provide a sealed electrical interface to withstand harsh environments and constant UV exposure. The Endurance S2 product line enables daisy chain connection of both nodes without requiring additional connector components. This eliminates parts and saves time, reducing the overall cost of the luminaire.

Authors

- Jonathan Catchpole, Principal Systems Architect

- Scott Hamilton, Sr. Manager, Product Management

- Alexander Hunt III, Product Manager

About the Author

More Content by TE Connectivity