Content originally published in the 2021 High-Reliability, Harsh-Environment Connectivity eBook

Sensors have played a critical role within industrial factory floor applications for years. However, as factories are becoming more autonomous and IoT ready, the requirements for sensors are becoming more demanding. The latest sensor developments are being influenced by IoT trends including miniaturization, digitization, sensor fusion, lower power, and the integration of wireless communication technologies. Implementing these sensor trends while also enabling sensors to withstand the harsh environments often found on factory floors has proven to be challenging, but it is achievable with the right materials and designs. Accurate and reliable sensor data is important since reducing machine downtime in industrial applications is a critical consideration in terms of customer experience and profitability in IIoT applications.

Condition monitoring systems are designed to determine if equipment is operating correctly and identify when it is starting to degrade. Typically, an assessment is performed to identify important equipment as well as common failure modes. That information can then be used to select sensors to monitor specific components of the equipment and provide the data necessary to determine potential machine degradation and failure modes. Whether it is an accelerometer monitoring high-frequency vibrations in a piece of rotating machinery or a temperature sensor detecting an overheating condition in a motor bearing, it is critical to select the proper sensor technology to monitor and detect potential failure modes to ensure increased uptime of critical equipment on the factory floor. Vibration, fluid property, pressure, temperature, humidity, speed, and position sensors can all play a critical role in industrial applications. These industrial sensors, along with the right analytics, can help reduce downtime by predicting machine failures, increasing productivity, lowering maintenance costs, and improving worker safety.

The following five sensor technologies are key to achieving reduced downtime for critical machinery in harsh industrial operating environments.

Vibration Sensors

For industrial machinery, abnormal vibration is a leading indicator that maintenance is required. Each piece of equipment has its own unique vibration signature for normal operation. Accelerometers can monitor both the magnitude and frequency of equipment vibration. Increases in the magnitude of vibration or vibrations that occur at higher or different frequencies will indicate a change in equipment’s vibration signature. Vibration information can be used to determine the need to service equipment and can even be used to pinpoint the specific component or components that need to be repaired or replaced. Vibration sensors can be used to measure slight changes in vibration for predictive and preventive maintenance applications, ensuring factory operations stay up and run efficiently. Sensors can be embedded within the controls and equipment using board mountable accelerometers or mounted externally using ruggedized and sealed plug-and-play or wireless accelerometers. Industrial accelerometers need to be designed and manufactured to withstand the rigors of general industrial applications with high sensitivity, resolution, and bandwidth to accurately monitor varying levels of vibration in critical machine applications.

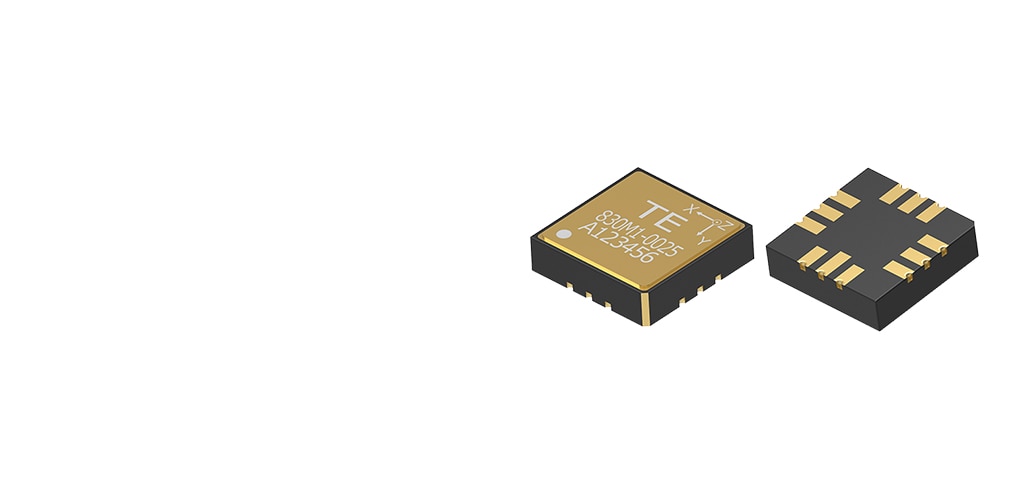

830M1

Triaxial Embedded 830m1 Accelerometer

As factories are becoming more automated, sensors are being used to capture critical performance data for improved efficiency of factory machinery. The triaxial embedded 830M1 accelerometer from TE Connectivity offers advanced acceleration sensing for machine health monitoring in applications where wide bandwidth, small size, low power, and robust performance are essential.

Pressure Sensors

Pressure sensors are used to measure liquid or gas pressure in applications ranging from industrial process control and HVACR systems to industrial pumps and compressors and, as such, must often be made to reliably withstand exposure to severe media such as contaminated water and mildly corrosive fluids. Pressure sensors also play a critical role in industrial applications like process control and monitoring, pumps and compressors, and a wide range of pneumatic and hydraulic systems. Low-pressure sensors can be used to monitor air flow in HVACR systems, as well as to determine when filters need to be replaced. As factories are becoming smarter and more connected, companies are deploying more intelligent and sophisticated solutions. Some pressure sensors now have built-in Bluetooth connectivity, which allows for wireless monitoring while maintaining high performance in rough industrial environments.

Ideal for use in smart factories, the M5600 wireless pressure transducer from TE Connectivity’s Microfused line is enclosed in a stainless steel and polycarbonate housing and is designed to withstand harsh industrial environments.

Temperature and Humidity Sensors

Temperature is the most widely sensed environmental parameter, and it plays a key role in condition monitoring and other industrial applications. A variety of technologies are implemented to monitor the temperature of everything from stator windings to bearings and much more. Temperature can be key to detecting wear, overload, and other conditions that can lead to premature equipment failure and corresponding downtime. Humidity sensing, in conjunction with temperature sensing, can be critical to the control and efficiency of a range of industrial processes. including those involving paints, solvents, and inks used for printing. Employee comfort and productivity are important considerations in most industrial facilities as well, and the monitoring and control of both humidity and temperature within a specified range have been shown to maximize productivity and help keep employees healthy. Non-contact temperature sensors, such as infrared thermopiles, are also used in body temperature scanning systems to help monitor employee wellness and in rotating equipment and other applications where physical contact with machinery is not possible.

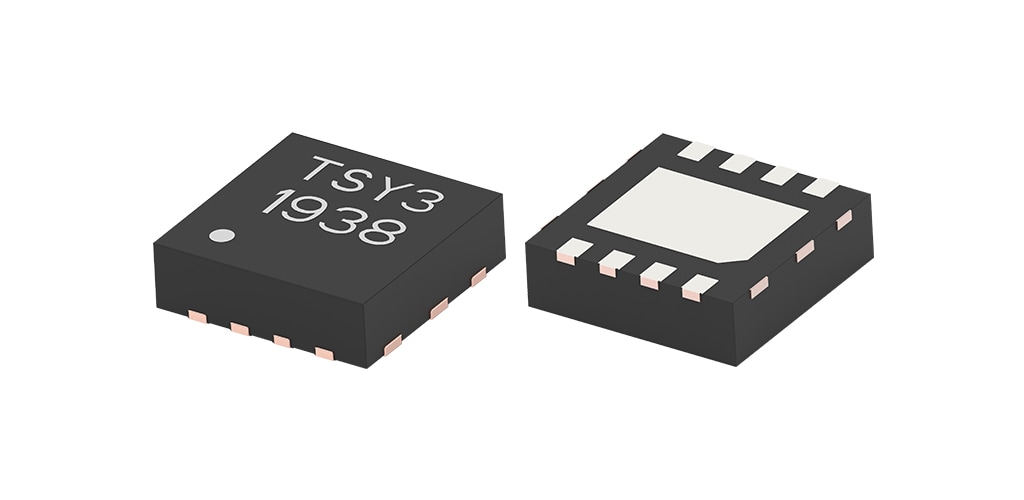

TSYS03 Digital Temperature Sensor

Designed for precise temperature sensing in applications with serious space constraints, TE Connectivity's TSYS03 digital temperature sensor features an industry-leading miniature XDFN6 package equipped with digital output and configurable I²C addresses.

HTU31D Humidity and Temperature Sensor

Designed to quickly provide precise humidity measurements, TE Connectivity's HTU31D sensor offers sustained performance even when exposed to extreme temperature and humidity.

Position Sensors

Position sensors are used to provide the precise feedback needed to efficiently and effectively monitor and control a wide range of industrial machinery, including drilling equipment, CNC machines, industrial robotics, and automation equipment. However, the hazards common to industrial environments, including temperature extremes, humidity, dirt, debris, and constant shock and vibration, pose serious challenges for many sensors. Anisotropic magneto strictive (AMR) position sensors are one technology proven to provide accurate and reliable position sensing in harsh industrial environments. AMR sensors are also relatively insensitive to changes in temperatures and magnetic field strength. Other technologies, such as linear variable differential transformers (LVDTs), precision potentiometers, and cable extension sensors (e.g., string pots) are utilized in several industrial position sensing applications.

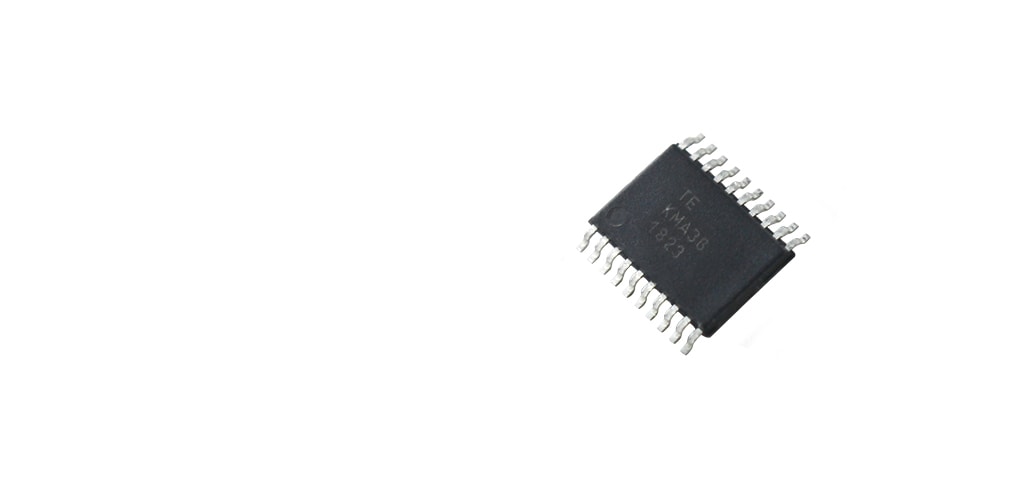

KMA36 Contactless Magentic Encoder

Designed for industrial applications where digital output and high accuracy are essential, TE Connectivity's KMA36 contactless magnetic encoder uses AMR technology to sense rotary and linear position.

Fluid Property Sensors

Industrial environments require effective, multi-parametric solutions for monitoring lubricants and oils utilized in equipment and systems. Fluid property sensors are designed to continuously monitor oil and lubricant properties, ensure that they are working effectively, and indicate when they need to be replaced, as lubrication is essential for both efficient machine operation and maximizing the longevity of the equipment. The industrial environments in which these sensors are used are often quite challenging, with high levels of dirt and vibration and significant temperature swings. So, in order to provide accurate and reliable data, these sensors must be housed in rugged packaging and optimized to withstand years of exposure to harsh conditions while still providing durable, long-term performance.

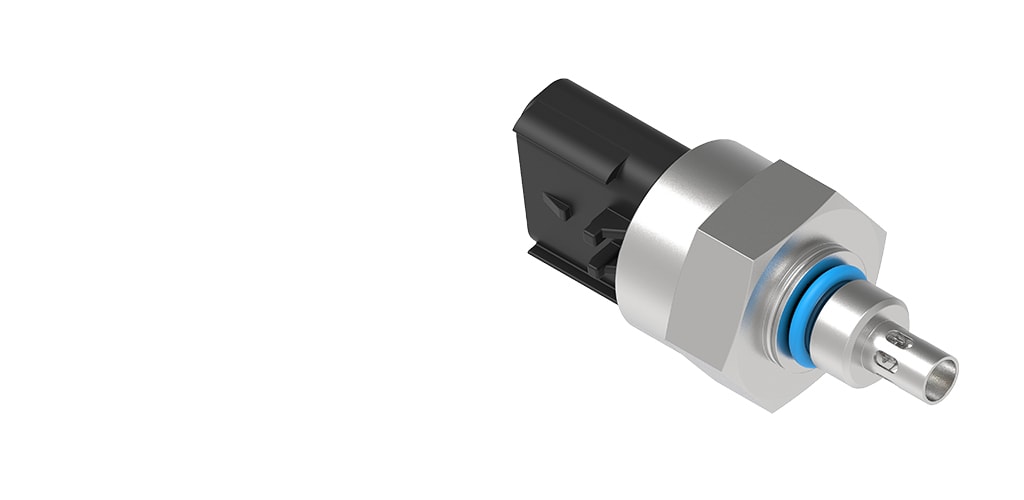

FPS2800 Oil Property Sensor

Optimized for oil condition monitoring, TE Connectivity's FPS2800 oil property sensor is designed to measure multiple physical properties of fluids. By leveraging tuning fork technology, this single sensor can simultaneously measure dynamic viscosity, density, dielectric constant, and temperature to provide enhanced fluid analysis.

About the Author

More Content by TE Connectivity